Due to the expected decrease in accidents, fully autonomous trucks often bring feelings of uncertainty to virtually anyone involved in the collision repair industry. However, as was discussed during the 3rd installment of the HD Repair Forum’s webinar series; there is a silver lining.

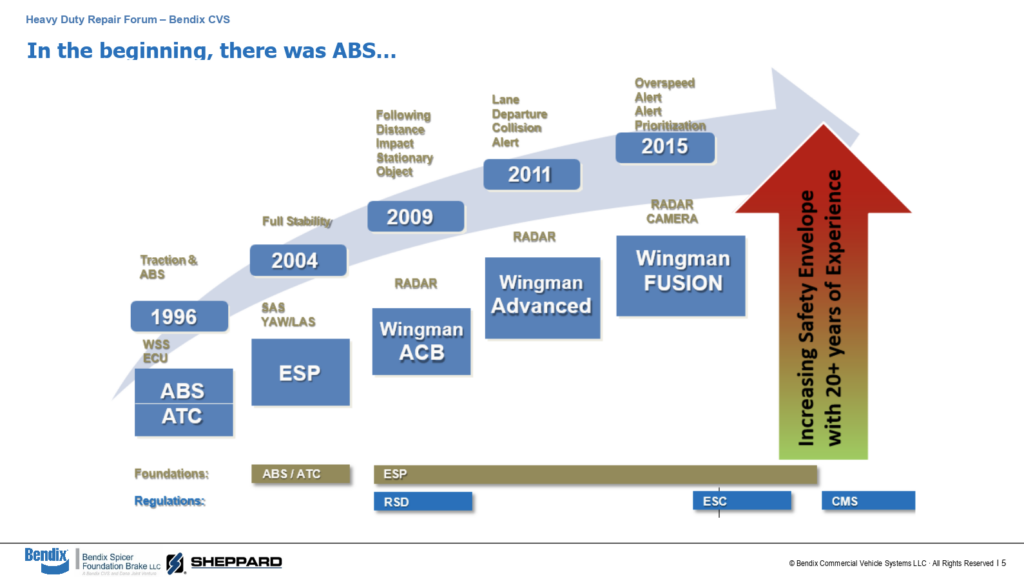

It’s true, collision avoidance systems aren’t new technology. The industry was exposed to early forms of these systems years ago with the implementation of anti-lock brake systems (ABS). However, truck manufacturers continue incorporating additional ADAS features into their vehicles at an accelerated rate. Understanding the technology and repairability of these technical features is extremely important for repairers to gain a foothold of, because accidents are still going to happen and your credibility and liability are on the line.

A company heavily involved in vehicle technology and of increasing importance to the heavy-duty collision repair industry is component manufacturer, Bendix Commercial Vehicle Systems. Recently, administrators at the HD Repair Forum brought representative Jim Barber of Bendix, forward to speak directly with collision repairers in an one hour segment titled, “Evolve Your Business to Keep Up with ADAS Equipped Vehicles.” The newest OEM technical additions, the importance of proper repair and operation of the technological additions before returning affected vehicles to customers, as well as technological terms such as YAW, LAS, and SAS were just a few topics of importance that were discussed.

Although full autonomy seems to be the end goal of vehicle technology developments, it is not here yet and will not be incorporated exactly as some may perceive. Barber laid out clearly to those in attendance that the industry’s projected path in implementing all five levels of vehicle autonomy will take some time, “Today, we’re currently into level 1 systems and we’re crossing into Level 2 systems…The Level 5 systems (where a driverless vehicle will be implemented) probably won’t be a reality until the 2040, 2050 time frame.” In fact, using the aviation industry as an example, he furthered this statement by adding, “We’ve had fly-by-wire aircraft for almost 30 years, where an aircraft can take off and land by itself… but yet the federal government still requires a pilot and a co-pilot.”

Still, the industry trend is to continue adding more sensors, gathering more information to achieve better performance, with driver lives and safety at the forefront. Thus, this educational episode was spent ensuring attendees understood the importance of getting acclimated with the latest additions in heavy- and medium-duty vehicle advance driver assistance systems) technology and that repair needs and processes are changing.

ADAS technology can be viewed as “building-block” technology, in which the newest ADAS technology is layered upon the pre-existing technology, or the ABS systems in this case. In other words, the ABS system serves as the foundation in which additional advanced driver assistance systems (ADAS) are built upon. An animated diagram provided during the webinar helped participants grasp the layering effect.

Understanding the building blocks of ADAS is an important message, because it will help diagnose and repair vehicles when it enters the shop, especially when the vehicle involved has Bendix Wingman and Fusion technology. Barber further clarified that each layer of added technology provides another message for the ECU to read, thus an action to deliver.

Essentially, the technology depends upon each other; ground-breaking comprehension in that each feature must be observed for complete functionality post-collision. The culmination of Wingman and Fusion components and technology brings the ABS, ECU (electronic controls unit), Radar and Camera together. “The camera may see something, but the radar does not, and it tells the system, no don’t worry about it, and vice versa…The system goes active when the two components agree.”

An underlying message for this webinar and even expressed as a question asked by a participant is, does a safe and proper repair begin with scanning the vehicle? Barber confirmed that every shop should have a document outlining the condition of that truck when it arrived at the shop, and more importantly the condition it was in upon delivery. The ACom Pro Diagnostics tooling and software referenced in the webinar is one such method to achieving that goal. It provides documented proof of active engine fault codes, battery voltage, and even provides technicians with needed information, such as the proper steps to recalibrate sensors. This is the documentation and proof that you need to show the fleet owner, insurance company or vehicle owner that you performed a safe and proper repair. It could mean the difference between a comeback, subsequent accident, fatality, or lawsuit.

Additional important messages were shared during this month’s webinar and included pre-scans and post-scans, steering angle sensor recalibration needs, proper replacement of cameras on windshields, which is OEM specific, and more.

For a complete review of the information shared in this webinar, sponsors of the HD Repair Forum Webinar Series have made this information available to the industry on demand. Simply register to watch this episode or previous episodes by following this link.